Why S890QL Steel Plates Are Ideal for Heavy Engineering Projects

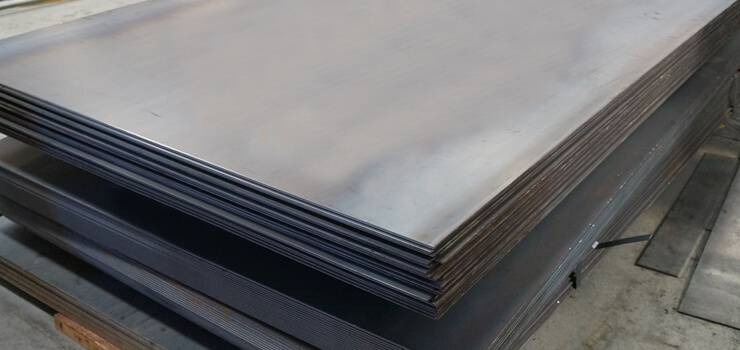

In the demanding world of heavy engineering, selecting the right material can make the difference between structural success and project failure. One such material that continues to gain popularity across industries is S890QL High Strength Steel Plates. Known for their exceptional strength and durability, these plates are tailor-made for applications where high load-bearing capacity, resistance to wear and tear, and superior performance are non-negotiable.

Let’s explore why S890QL Steel Plates are a smart choice for heavy-duty engineering and construction environments.

What Are S890QL High Strength Steel Plates?

S890QL is a high yield structural steel grade developed in accordance with EN 10025-6 standards. It belongs to the category of quenched and tempered steels, which means it undergoes a specific heat treatment process to achieve high strength and toughness. The “S” stands for structural steel, “890” indicates the minimum yield strength in MPa, and “QL” denotes the steel’s suitability for low-temperature applications.

Key Mechanical Properties:

-

Yield strength: Minimum 890 MPa

-

Tensile strength: Between 940–1100 MPa

-

Excellent toughness at low temperatures (up to -40°C)

-

Good weldability despite high strength

These mechanical properties make S890QL High Strength Steel Plates a perfect match for high-load applications.

Benefits of Using S890QL Steel in Heavy Engineering

1. High Load-Bearing Capacity

In heavy engineering, equipment and structures are subjected to extreme pressure. The high yield strength of S890QL steel ensures maximum load resistance with minimal deformation, allowing for lighter designs without compromising safety or integrity.

2. Weight Reduction Without Strength Loss

Using S890QL High Strength Steel Plates allows engineers to reduce the thickness of steel used in a project. This means lighter overall structures, which translates to cost savings on materials, easier transportation, and lower structural stress.

3. Enhanced Durability and Toughness

These plates offer excellent impact resistance, especially at sub-zero temperatures. This is a crucial factor in projects like mining, offshore drilling, and bridge construction, where environmental conditions are harsh and unpredictable.

4. Superior Weldability

Despite being a high-strength steel, S890QL maintains good weldability due to its controlled carbon content and optimized alloying. This makes it easier for manufacturers to fabricate and assemble parts without the risk of cracking or weakening the material.

Typical Applications of S890QL Plates in Heavy Engineering

The unique combination of strength, toughness, and weight efficiency makes S890QL High Strength Steel Plates indispensable in several sectors:

Cranes and Lifting Equipment

High-rise cranes and hydraulic lifting arms require steel that won’t bend or crack under pressure. S890QL delivers that reliability with a reduced cross-section, enabling lighter, more efficient equipment designs.

Heavy-Duty Machinery

Bulldozers, excavators, and other earth-moving machines benefit from the high wear resistance and strength of S890QL plates, extending the service life of vital components.

Bridges and Infrastructure

Modern bridges are designed with minimalistic aesthetics but maximum durability. S890QL plates help create slimmer yet stronger girders and support structures, ideal for long-span bridge construction.

Offshore Platforms and Marine Structures

Operating under high loads and in corrosive environments, offshore and marine platforms demand steels like S890QL that can endure extreme stress and tough conditions without failure.

Load-Bearing Structures in Buildings

From steel frames to support beams, S890QL contributes to stronger and more efficient high-rise constructions, allowing architects and engineers to push the boundaries of modern design.

Why Engineers and Designers Prefer S890QL

Choosing materials for a project isn’t just about strength — it’s about performance, efficiency, safety, and cost. Here’s why S890QL is often a go-to option:

-

Optimized Structural Performance: The combination of yield strength and ductility ensures that the structure behaves predictably under stress.

-

Cost-Efficient: Reducing the volume of steel needed (due to high strength) leads to savings in raw material, fabrication, and logistics.

-

Versatility: Suitable for both static and dynamic loads, S890QL performs well across a wide range of applications and environments.

-

Sustainability: Lighter structures mean less energy used in transport and installation, contributing to eco-friendly project outcomes.

Key Standards and Certifications

S890QL High Strength Steel Plates conform to EN 10025-6 standards and are available with:

-

CE marking (for structural use in Europe)

-

EN 10204 3.1 and 3.2 certifications

-

Ultrasonic testing

-

Low-temperature notch impact testing (Charpy V-notch)

These certifications ensure quality and reliability for global engineering standards.

Things to Consider Before Using S890QL Plates

While the advantages are clear, there are a few technical considerations when working with S890QL:

1. Preheating During Welding

Due to its high strength, S890QL may require preheating before welding, especially for thick sections. This prevents issues like cold cracking.

2. Cutting and Machining

Extra care is needed during cutting and machining. CNC and plasma cutting techniques are typically recommended for precision and reduced thermal damage.

3. Proper Handling and Storage

To maintain plate quality, it should be stored in dry environments and handled with equipment that avoids excessive bending or scratching.

Conclusion

In summary, S890QL High Strength Steel Plates offer a rare combination of strength, lightness, toughness, and reliability. Whether it’s for lifting equipment, infrastructure, marine platforms, or structural components, these plates elevate engineering outcomes while keeping costs and environmental impact in check.

For engineers, builders, and project managers seeking to optimize performance without compromising safety, S890QL is not just a material — it’s a solution.

Leave a Comment