IECEx Inspection Software for International Compliance in Hazardous Locations

In industries where hazardous areas are part of daily operations—such as oil and gas, petrochemicals, mining, and manufacturing—the safe management of explosive atmospheres (EX) equipment is critical. Traditional paper-based records or outdated spreadsheets are no longer sufficient for modern operations. Enter iecex inspection software—a smarter, digital solution to streamline how companies track, inspect, and manage both their EX equipment register and hazardous equipment register efficiently, accurately, and in compliance with international standards.

What Is EX Inspection Software?

EX inspection software is a specialized digital tool designed to automate and improve the process of managing equipment used in explosive or hazardous environments. This type of software enables organizations to:

-

Maintain a centralized EX equipment register.

-

Schedule and track inspections in real time.

-

Ensure compliance with ATEX, IECEx, NEC, and other safety regulations.

-

Eliminate human errors in documentation and tracking.

-

Improve asset visibility and reporting for audits.

Unlike manual systems, EX inspection software integrates all necessary data into one platform, allowing for better decision-making, faster response to maintenance needs, and improved safety compliance.

Key Features of EX Inspection Software

-

Centralized Equipment Register

A digital EX equipment register allows you to store all relevant information about hazardous area equipment in one secure, cloud-based location. Each piece of equipment can be tagged with details like model, manufacturer, certification status, location, and inspection history. This eliminates the need for spreadsheets or paper-based tracking and improves data accuracy. -

Inspection Scheduling and Alerts

The software automates the scheduling of periodic inspections based on predefined intervals. It sends alerts and reminders to technicians and managers to ensure timely inspections, reducing the risk of missed or overdue checks. -

Real-Time Reporting and Analytics

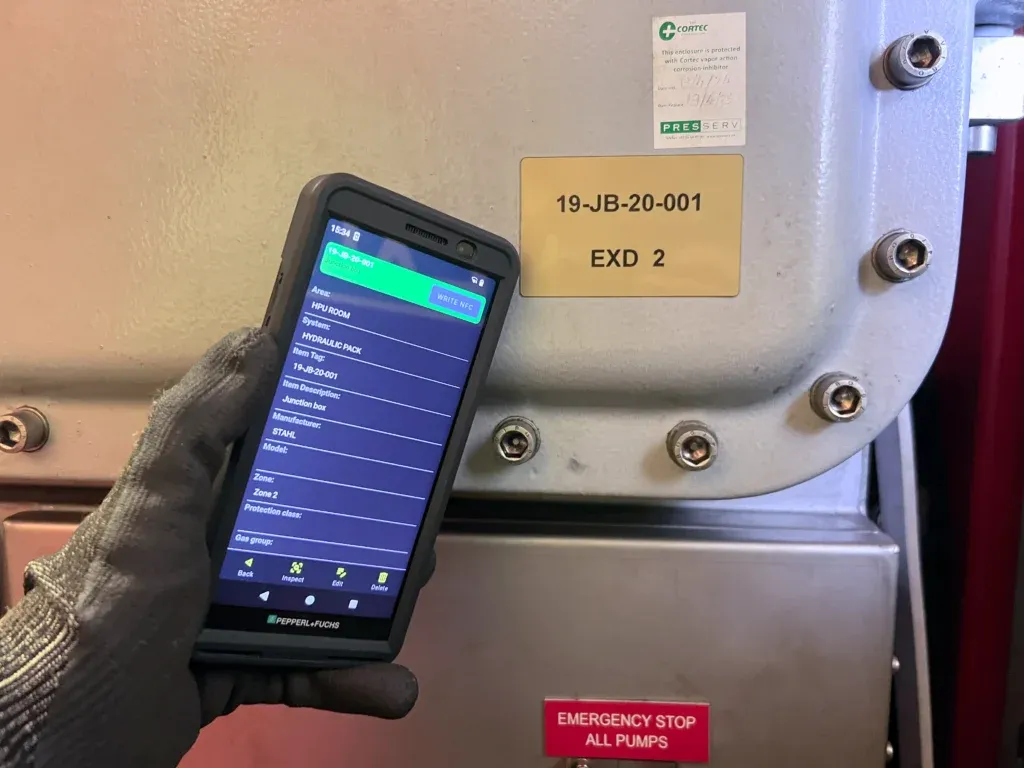

EX inspection software enables real-time data entry during inspections via mobile devices or tablets. This allows for instant uploading of photos, annotations, and digital signatures. Dashboards and analytics offer a visual overview of equipment status, compliance metrics, and performance trends. -

Compliance Management

Staying compliant with safety standards such as IEC 60079 or ATEX Directive 2014/34/EU is vital. EX inspection software keeps a digital trail of all inspections, findings, and corrective actions, which can be easily accessed during audits. -

Customizable Forms and Checklists

Technicians can use customizable checklists tailored to specific zones, asset types, or compliance requirements. This ensures that inspections are consistent and thorough, regardless of the technician conducting them. -

Mobile Accessibility

Many EX inspection software platforms come with mobile apps that allow technicians to access equipment records, checklists, and instructions even in remote field locations. This is crucial for hazardous sites where connectivity may be limited.

Benefits of Using EX Inspection Software

1. Improved Safety and Risk Management

By ensuring that all hazardous equipment is regularly inspected and maintained, EX inspection software helps prevent equipment failure, explosions, and other workplace hazards. Automated alerts reduce the likelihood of missed inspections and promote proactive safety measures.

2. Increased Efficiency and Productivity

Technicians no longer need to fill out paper forms or re-enter data into spreadsheets. This streamlines workflows, allowing more time to be spent on actual inspections and maintenance rather than administrative tasks.

3. Cost Savings

By reducing equipment downtime, minimizing human error, and streamlining reporting and compliance, companies can save significantly on operational costs. The predictive maintenance features can also help avoid expensive emergency repairs or penalties for non-compliance.

4. Enhanced Data Integrity and Traceability

Digital records are easier to manage, search, and retrieve compared to paper files. Each inspection and action is timestamped and logged, ensuring full traceability for internal reviews or external audits.

5. Scalability

Whether you manage a single facility or multiple global sites, EX inspection software can scale with your business. It allows standardization of inspection procedures across sites and provides central visibility into all hazardous area equipment.

Why Upgrade Now?

Many companies still rely on outdated systems or fragmented methods for managing their EX equipment and hazardous area registers. These systems often lead to inefficiencies, lost data, inconsistent inspections, and increased safety risks. By upgrading to a modern EX inspection software platform, you are not only investing in compliance and safety but also positioning your business for smarter asset management and operational excellence.

Furthermore, with stricter global regulations and heightened scrutiny in hazardous environments, digital tools are rapidly becoming industry standard rather than a luxury. Investing now can help you stay ahead of regulatory changes and future-proof your safety and maintenance processes.

Choosing the Right EX Inspection Software

When evaluating EX inspection software, consider the following factors:

-

Regulatory compatibility: Ensure the software supports your specific compliance requirements (ATEX, IECEx, NEC, etc.).

-

Ease of use: The user interface should be intuitive for both technical and non-technical users.

-

Mobile functionality: Essential for field operations and real-time data capture.

-

Customization: The ability to create or modify inspection templates and workflows.

-

Support and training: Check for ongoing technical support and training options to onboard your team.

Some popular EX inspection software solutions on the market include industry-specific platforms designed with built-in hazardous area management tools, API integrations, and offline capabilities.

Final Thoughts

Adopting EX inspection software is no longer optional for industries dealing with hazardous environments—it’s a necessity. This powerful tool not only streamlines your inspections and improves data accuracy but also enhances workplace safety, ensures regulatory compliance, and saves time and money.

Leave a Comment