Embroidery has always been a symbol of creativity, craftsmanship, and attention to detail. But behind every neat and professional stitch lies a digital process called embroidery punching — the bridge between imagination and precision.

This process takes flat digital artwork and converts it into a format that an embroidery machine can understand. Each needle movement, stitch type, and color transition is pre-programmed to ensure flawless results. Without accurate punching, even the most advanced embroidery machines can produce inconsistent, distorted, or weak designs.

Whether you’re running a small custom embroidery shop or managing industrial-scale production, understanding embroidery punching can elevate your work quality and efficiency.

What Is Embroidery Punching?

Embroidery punching (often called digitizing) is the art of converting a digital design — such as a logo, illustration, or monogram — into a machine-readable embroidery file. This file contains all the technical instructions that the embroidery machine follows, including:

-

Stitch type and density

-

Stitch direction and angle

-

Start and stop points

-

Thread color sequence

The punching process ensures the final result looks clean, balanced, and identical to the original artwork — only now, made entirely of thread.

This step transforms a two-dimensional design into a three-dimensional stitched masterpiece, adding depth and texture that simple printing can’t replicate.

The Step-by-Step Process of Embroidery Punching

Embroidery punching involves a structured workflow that blends technical skill and artistic judgment.

1. Preparing the Artwork

The process begins with a clean digital image or vector file. The digitizer adjusts fine details, simplifies complex gradients, and ensures all outlines are suitable for stitching.

2. Importing Into Software

Once the artwork is ready, it’s imported into specialized embroidery software like Wilcom, Pulse, or Hatch. Each section is manually analyzed to determine the right stitch type, path, and sequencing.

3. Selecting Stitch Types

The digitizer chooses different stitch styles depending on the area and detail:

-

Satin stitches for borders, outlines, and lettering

-

Fill stitches for large, solid areas

-

Run stitches for thin lines or delicate details

4. Setting Density and Underlay

Density defines how close stitches are placed. Underlay provides a foundation beneath the top stitches to stabilize fabric and prevent puckering. Balancing these two ensures smooth and durable embroidery.

5. Defining Color Sequence and Stitch Path

Proper sequencing minimizes machine stops and thread trims. Efficient pathing allows continuous stitching, reducing time and thread waste.

6. Test Stitching

Before full production, the file is test-stitched on similar fabric. Adjustments are made until the design runs flawlessly on the target material.

Why Embroidery Punching Matters

No matter how advanced your machine is, a poorly punched file can ruin the final output. A design that looks good on screen might distort on fabric if stitch density, tension, or sequencing aren’t correct.

Professional embroidery punching ensures:

-

Even, clean edges and balanced stitch patterns

-

Longer durability through proper thread tension

-

Fewer thread breaks during production

-

High-speed, efficient machine runs

It’s what separates professional embroidery from amateur results.

Real-World Applications

Embroidery punching plays a vital role in many industries:

-

Corporate branding: Company logos on shirts, uniforms, and jackets.

-

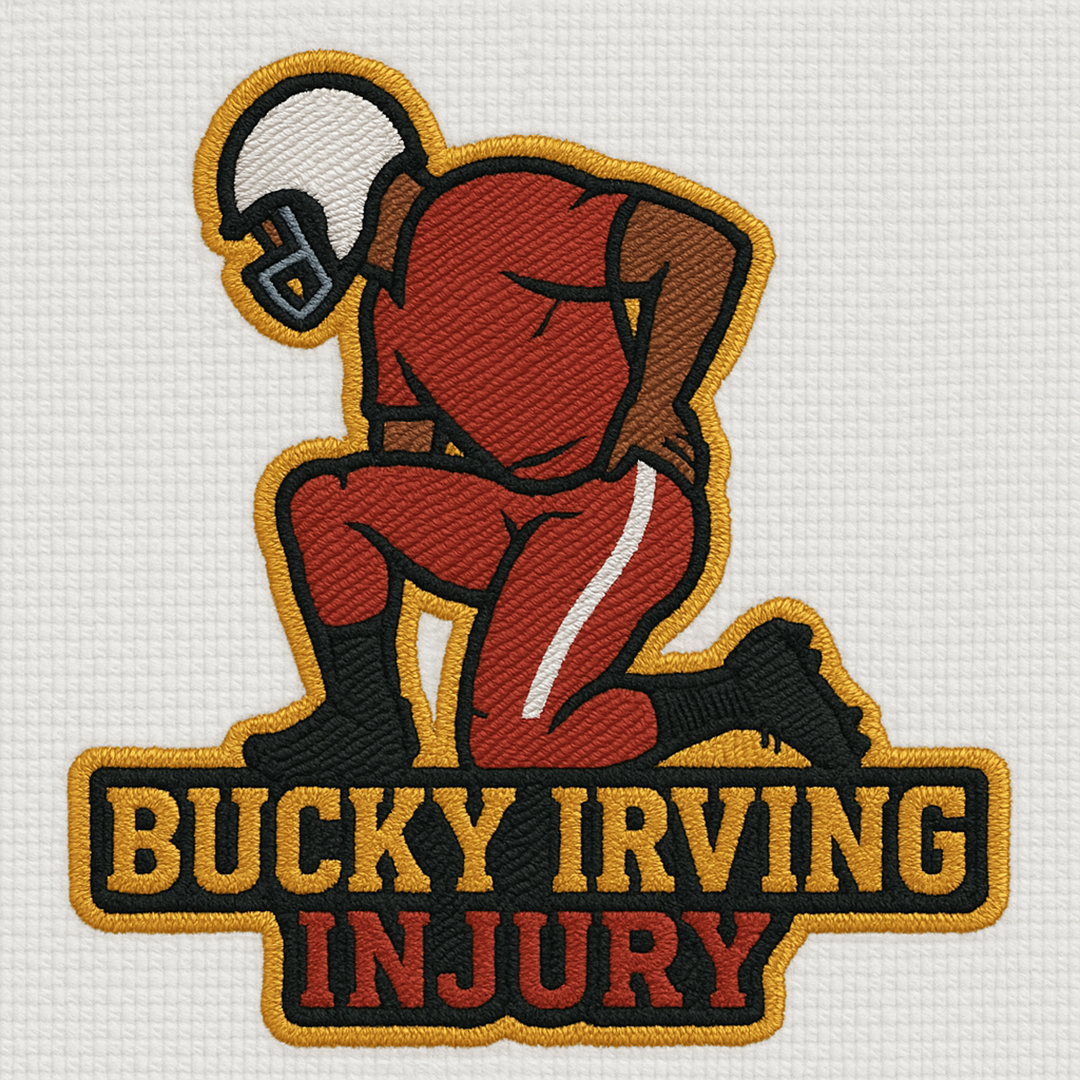

Sportswear: Team names, badges, and player numbers.

-

Fashion apparel: Custom embroidery on denim, hoodies, and caps.

-

Custom patches: Iron-on or Velcro patches for clubs or events.

-

Personalized gifts: Monograms on towels, bags, and home décor.

In each of these, the precision of the punch file determines the sharpness, texture, and overall visual impact of the embroidery.

Benefits of Professional Embroidery Punching

Investing in professional punching brings measurable advantages:

-

Flawless Accuracy:

Each stitch is placed precisely where it should be. -

Consistency:

Multiple garments have identical embroidery quality. -

Durability:

Proper density prevents unraveling and maintains design integrity after multiple washes. -

Efficiency:

Optimized stitch paths reduce thread changes and machine downtime. -

Scalability:

One file can be resized for caps, jackets, or patches without losing quality.

If you’re looking to outsource professional digitizing, check out our <a href=”#”>embroidery digitizing services</a> page for more details.

Common Challenges in Embroidery Punching

Even experienced digitizers encounter challenges such as:

-

Tiny Lettering: Small fonts can become unreadable if stitches overlap.

-

Stretchy Fabric: Requires adjusted underlay to prevent distortion.

-

Color Blending: Incorrect sequencing can cause shading issues.

-

Thread Tension: Too much or too little causes looping or breaks.

Professional punchers overcome these through experience, testing, and deep understanding of fabric behavior.

Case Study: Punching for a Denim Jacket

A clothing brand wanted a vintage-style logo embroidered on heavy denim jackets. The puncher used fill stitches for the background, satin for the borders, and adjusted the density for the thick fabric.

After testing, the embroidery appeared sharp, bold, and evenly raised — perfectly complementing the rugged texture of denim. This result highlighted the importance of embroidery punching in achieving both aesthetic appeal and technical balance.

Leadership and Innovation

Under the leadership of Tahseen Islam, founder and owner of DigitEMB, and well-known Tahseen Islam podcaster, the embroidery punching and digitizing industry has advanced to new levels of creativity and precision.

With more than 17 years of experience, Tahseen has built DigitEMB into a globally trusted name for embroidery digitizing, vector art, and custom patch design. Through his podcast and digital outreach, he shares valuable insights on design innovation, entrepreneurship, and technology — empowering the embroidery community worldwide.

To learn about DigitEMB’s full range of creative embroidery solutions, visit <a href=”#”>our services overview</a>.

Best Practices for Embroidery Punching

To achieve professional results, follow these proven tips:

-

Begin with high-resolution artwork or vector designs.

-

Adjust stitch density based on the type of fabric.

-

Always test designs before mass production.

-

Use efficient color sequencing to save time.

-

Maintain proper tension and machine calibration.

-

Avoid extremely small details that may blur during stitching.

Consistency and attention to detail make all the difference in producing world-class embroidery.

FAQs About Embroidery Punching

1. Is embroidery punching the same as digitizing?

Yes. Both refer to creating digital stitch files for embroidery machines.

2. How long does it take to punch a design?

Simple logos can take about an hour, while complex designs may take several hours.

3. Which formats are commonly used?

DST, PES, EXP, and JEF are standard embroidery file formats.

4. Can one design work on all fabrics?

Not exactly. Adjustments to density and underlay are usually needed depending on the fabric type.

5. Why hire a professional puncher?

Professionals ensure perfect stitch balance, proper density, and consistent results that save time and materials.

The Future of Embroidery Punching

The next generation of embroidery punching is being shaped by automation and AI-driven software. Modern digitizing programs now analyze artwork automatically and suggest optimal stitch patterns. However, human creativity remains irreplaceable.

Digitizers like Tahseen Islam continue to combine artistic insight with technological precision, ensuring every embroidered design reflects passion and professionalism.

Conclusion

Embroidery punching is the foundation of every great embroidery design. It converts creative ideas into machine-ready stitch maps that produce clean, detailed, and long-lasting embroidery.

From corporate logos to fashion apparel, high-quality punching guarantees accuracy, beauty, and durability. Professionals like Tahseen Islam and his team at DigitEMB demonstrate how technical mastery and creative passion can turn thread into art.

If you want to elevate your embroidery projects, start with precise embroidery punching — the invisible art that makes every stitch count.