Advanced CNC Programming Tips to Boost Efficiency

In the world of modern manufacturing, CNC programming has become the backbone of precision engineering. While basic knowledge of CNC programming allows for creating functional parts, advancing your skills can significantly improve efficiency, reduce cycle times, and minimize costly errors. This article dives into advanced CNC programming tips to help machinists and programmers elevate their game and get the most out of their CNC machines.

From optimizing tool paths to implementing subroutines, mastering these techniques can lead to increased productivity and a more streamlined workflow. Whether you are a seasoned CNC programmer or looking to advance from intermediate knowledge, these insights will provide practical value and boost operational efficiency on the shop floor.

Optimize Tool Paths for Speed and Precision

One of the most powerful ways to enhance your CNC programming efficiency is by optimizing tool paths. Efficient tool paths not only reduce machine cycle times but also extend the life of your cutting tools. Instead of relying solely on standard zig-zag or contour tool paths, explore advanced strategies like high-speed machining (HSM) or trochoidal milling, which maintain consistent chip loads and minimize tool wear.

Using CAM software that supports adaptive clearing can significantly boost CNC programming outcomes. Adaptive clearing maintains a constant engagement angle, reducing the number of rapid moves and idle tool passes. It allows deeper cuts with faster feed rates, resulting in quicker material removal and less stress on the machine. These tool path improvements can translate into noticeable productivity gains over time.

Leverage Subprograms and Macros for Reusability

Subprograms and macros are invaluable tools in advanced CNC programming. They allow repetitive machining tasks to be encapsulated into reusable code blocks. Instead of duplicating code for similar operations across different parts or setups, you can write a single subprogram and call it multiple times, making your G-code cleaner and easier to manage.

Macros go a step further by enabling conditional logic and parameterized inputs. This opens up opportunities for automation within the CNC program. For instance, you can create macros that automatically adjust tool offsets or switch operations based on workpiece dimensions. Mastering these techniques not only improves code maintainability but also adds flexibility to your machining processes, allowing quick adaptation to new jobs with minimal manual rewriting.

Use G-Code Customization for Precision Control

Standard CNC programming practices rely on fixed post-processors, but advanced users can benefit significantly from customizing G-code. Tailoring G-code to the specific capabilities of your CNC machine allows for more precise control over every movement and action. This includes optimizing spindle speeds, feed rates, coolant commands, and tool change sequences for the best performance on a given machine.

Advanced G-code editing also includes using canned cycles effectively for operations like peck drilling, tapping, and roughing. These cycles reduce the complexity of code and improve machine efficiency. Furthermore, understanding modal commands and how to use them to reduce redundant instructions helps streamline the code for faster execution. Precision G-code customization ensures your machine is performing optimally, avoiding unnecessary wear and tear while delivering high-quality parts.

Implement Advanced Tool Management Strategies

Tool management is a critical but often overlooked aspect of CNC programming. With advanced tool management techniques, you can ensure consistent machining quality while reducing downtime caused by tool breakage or wear. Begin by assigning specific tool numbers and offsets in your program and ensuring consistency between the CNC machine and tool library in your CAM software.

Implementing tool life monitoring and automated tool change routines can make a big difference in high-volume production environments. Some machines allow you to set maximum tool life in terms of time or usage cycles. When the tool reaches its limit, the program automatically calls a replacement tool from the magazine. This reduces human error and keeps the production line running smoothly. Effective tool management is not just about organizing tools—it’s about integrating smart systems that ensure reliability and reduce human intervention.

Simulate and Validate Programs Before Execution

No matter how experienced you are in CNC programming, always simulate your code before executing it on the machine. Modern CAM software offers sophisticated simulation environments that allow you to verify tool paths, detect potential collisions, and analyze cutting forces. This step is essential to prevent costly mistakes and machine damage that can result from overlooked errors.

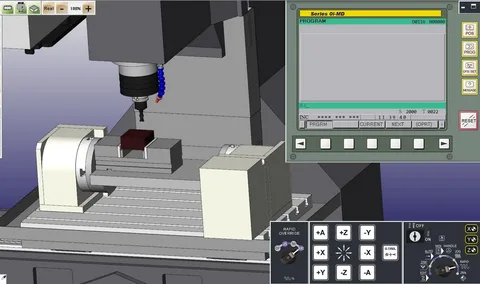

Beyond just visual validation, some simulation tools provide time and material usage estimates, which help in production planning and cost forecasting. Many shops use digital twins of their CNC machines, which emulate the real-world behavior of the machine in a virtual space. Simulating the CNC programming process enables safe experimentation with advanced techniques and fine-tuning parameters without risking real equipment or materials. This practice is a hallmark of efficient, professional machining operations.

Conclusion

Mastering CNC programming isn’t just about writing G-code—it’s about implementing strategic techniques that enhance productivity, precision, and safety. By optimizing tool paths, leveraging subprograms and macros, customizing G-code, managing tools efficiently, and validating programs through simulations, CNC programmers can elevate their skill sets and improve shop performance.

Each of these advanced CNC programming tips represents a step toward more efficient machining, reduced downtime, and higher part quality. As the industry evolves and machines become more capable, staying ahead means continually refining your CNC programming techniques and embracing the tools and methods that lead to smarter manufacturing.

Leave a Comment