Choosing a Reliable Automated Assembly System Supplier for Modern Manufacturing

Manufacturing industries across the world are undergoing a major transformation. Rising production volumes increasing quality expectations and growing labor challenges are driving companies to adopt advanced automation solutions. At the center of this evolution are automated assembly systems that bring speed accuracy and consistency to complex production processes.

Selecting the right automated assembly system supplier is no longer a simple procurement decision. It is a strategic investment that directly affects operational efficiency product quality and long term competitiveness. Manufacturers also depend heavily on advanced welding technologies to support automated production lines which makes collaboration with experienced arc welding machine suppliers equally important.

Companies such as Taylor Winfield Technologies have built a strong reputation by delivering integrated automation and welding solutions designed specifically for demanding industrial environments.

The Importance of Automated Assembly in Today’s Industry

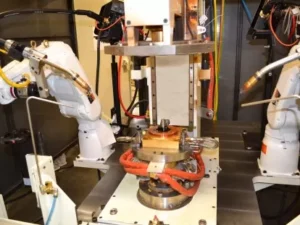

Automated assembly systems replace or enhance manual operations by using robotics precision tooling sensors and intelligent control systems to assemble components with exceptional repeatability.

These systems are widely used in industries such as:

Automotive manufacturing

Aerospace and defense

Heavy equipment production

Appliance manufacturing

Electronics and electrical systems

Energy and infrastructure

Automation allows manufacturers to meet tight tolerances reduce defect rates and maintain consistent quality across large production volumes. It also helps address workforce shortages and improves workplace safety by reducing repetitive and hazardous manual tasks.

What Defines a Professional Automated Assembly System Supplier

A capable automated assembly system supplier provides more than machinery. They deliver complete engineered solutions tailored to each customer’s production goals and technical requirements.

Key capabilities include:

Process analysis and feasibility studies

Custom system design and engineering

Robotic integration and motion control

Precision tooling and fixtures

Vision inspection systems

Software development and PLC programming

Factory testing and validation

Installation and commissioning

Operator training and technical support

This end to end approach ensures the system performs reliably in real production conditions rather than only in controlled testing environments.

Taylor Winfield and Advanced Assembly Automation

Taylor Winfield Technologies is recognized for designing and building advanced automated assembly systems that support high volume and high precision manufacturing operations.

Their systems are engineered to integrate seamlessly with upstream and downstream processes such as welding forming inspection and material handling. This holistic design philosophy allows manufacturers to create streamlined production lines that maximize throughput while maintaining strict quality standards.

As an automated assembly system supplier Taylor Winfield focuses on:

Robust mechanical design for continuous operation

High accuracy positioning and repeatability

Flexible modular system architecture

Advanced control platforms

Compatibility with robotic and welding technologies

Long term serviceability

These qualities make their systems well suited for manufacturers seeking stable performance and scalability as production demands evolve.

The Critical Role of Welding in Automated Assembly

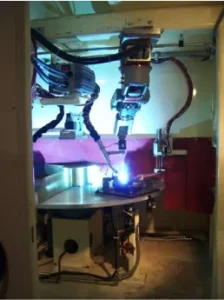

Welding is often a central operation within automated assembly lines especially in industries such as automotive heavy machinery and structural fabrication.

In these environments manufacturers rely on dependable arc welding machine suppliers to provide equipment capable of operating continuously with high accuracy and minimal downtime.

Arc welding systems must integrate with automated assembly platforms to ensure synchronized movement proper part positioning and consistent weld quality.

Key features of industrial arc welding systems include:

Stable arc control

Programmable welding parameters

Compatibility with robotic arms

Real time monitoring and fault detection

High duty cycle capability

Repeatable weld penetration and bead quality

Without reliable welding systems even the most advanced assembly automation cannot achieve optimal results.

Integration of Assembly Systems and Arc Welding Technology

One of the strengths of Taylor Winfield is its ability to deliver both automated assembly systems and advanced arc welding solutions as part of a unified production platform.

This integrated approach offers several advantages:

Reduced system integration complexity

Improved communication between machines

Consistent quality across all production stages

Simplified maintenance and training

Shorter commissioning times

Lower long term operating costs

When assembly systems and welding equipment are engineered together the result is a more stable and efficient manufacturing environment.

Engineering Driven Design Philosophy

Taylor Winfield applies an engineering first approach to every automated assembly project. Each system begins with a detailed evaluation of the customer’s product design material properties production targets and quality requirements.

Mechanical engineers controls specialists and automation experts collaborate to develop solutions that meet precise technical specifications.

Before shipment each system undergoes extensive factory testing including:

Cycle time verification

Accuracy and repeatability measurements

Safety compliance validation

Integration testing with welding and material handling equipment

Software performance testing

This rigorous process reduces installation risks and ensures rapid production startup.

Industries Served by Automated Assembly and Welding Systems

The combination of assembly automation and welding technology benefits a wide range of industries.

Automotive manufacturers use automated assembly lines for chassis body structures powertrain components and battery modules.

Heavy equipment producers rely on automation for assembling frames hydraulic systems and structural components that require high strength welds.

Appliance manufacturers depend on automated assembly to achieve uniform quality and high production volumes.

Aerospace companies use precision automation for complex assemblies where even minor defects are unacceptable.

Energy sector manufacturers apply automated systems to produce durable components for turbines pipelines and power generation equipment.

Across all these industries the partnership between an automated assembly system supplier and arc welding machine suppliers directly influences productivity and product reliability.

Quality Control and Process Monitoring

Modern automated assembly systems incorporate advanced quality assurance technologies to detect defects before products leave the production line.

These include:

Vision inspection systems

Laser measurement tools

Force and torque monitoring

Weld quality sensors

Data logging and traceability software

By capturing process data in real time manufacturers can identify trends optimize parameters and prevent costly failures.

Arc welding systems contribute to this quality framework by providing consistent heat input and penetration reducing the likelihood of weak joints or structural defects.

Long Term Service and Support

Industrial automation equipment represents a long term investment often operating for decades. A professional automated assembly system supplier must provide ongoing support throughout the system lifecycle.

Taylor Winfield supports customers with:

Preventive maintenance programs

Spare parts manufacturing and supply

Remote diagnostics

On site technical assistance

System upgrades and modernization

Process optimization services

This long term commitment ensures equipment remains productive reliable and compatible with future manufacturing technologies.

Similarly dependable arc welding machine suppliers maintain parts availability and technical expertise to support continuous production.

Advantages for Manufacturers

By partnering with a capable automated assembly system supplier and reliable arc welding machine suppliers manufacturers gain:

Higher production throughput

Improved product consistency

Lower defect and rework rates

Reduced labor dependency

Enhanced workplace safety

Lower long term operating costs

Improved scalability

These benefits translate directly into stronger market competitiveness and higher customer satisfaction.

The Future of Automated Assembly

Automation technology continues to evolve rapidly. Future assembly systems will incorporate:

Artificial intelligence for adaptive control

Advanced robotics with greater flexibility

Predictive maintenance algorithms

Digital twins for system optimization

Greater energy efficiency

Manufacturers who invest early in advanced automation and build partnerships with experienced suppliers will be best positioned to adopt these innovations.

Conclusion

In today’s manufacturing environment speed precision and reliability are essential for long term success. Choosing the right automated assembly system supplier ensures access to engineered solutions capable of meeting demanding production requirements.

At the same time collaboration with experienced arc welding machine suppliers provides the joining technology necessary to support strong durable assemblies within automated lines.

Through engineering excellence system integration and long term service support Taylor Winfield Technologies continues to help manufacturers build efficient scalable and future ready production systems.

For companies seeking to modernize operations improve quality and maintain competitiveness investing in advanced assembly automation supported by reliable welding technology is a strategic step toward sustainable growth.