How Carbon Wrapping for Beams Supports Load Redistribution

India’s construction sector is constantly evolving. From residential societies to commercial buildings, structural integrity is now a growing concern. Ageing structures, increased loads, and seismic vulnerabilities push the need for innovative solutions. One such solution, gaining widespread attention across India, is Carbon Wrapping for Beams.

Understanding Load Redistribution in Structural Systems

Every building uses its columns and beams to disperse loads. In particular, beams transfer bending forces over spans. Beams may deteriorate over time as a result of ageing, overloading, or seismic activity. The strain isn’t spread equally after that.

Other components of the structure are subjected to increased stress as one beam deteriorates. Cracks or even partial collapses may result from this imbalance. Restoring load distribution equilibrium becomes essential as a result. Techniques for reinforcement are useful in this situation.

The Rise of Carbon Wrapping Technology

In the past, concrete encasement or steel jacketing was used extensively in structural retrofitting in India. These techniques, however, add dead weight to structures and are labour-intensive.

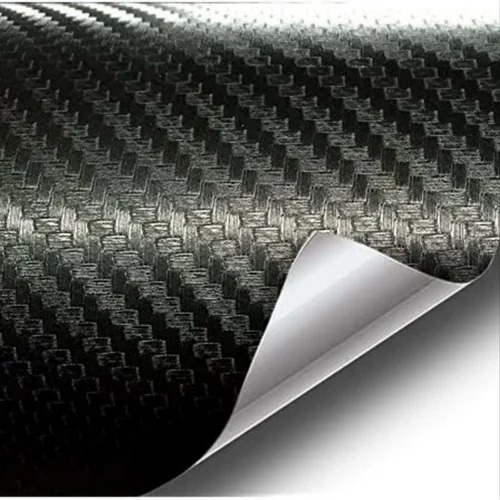

On the other hand, lightweight carbon fiber-reinforced polymer (CFRP) sheets are used in Carbon Wrapping for Beams. These are around strained or damaged beams. The outcome? Enhanced durability and effective load redistribution without the need for large materials.

This method works very well for retrofitting in cramped spaces because Indian cities frequently have little room.

How Carbon Wrapping Alters Load Behavior

Beams’ original behavior is changed by carbon wrapping. CFRP functions as an exterior reinforcement after it is applied. It improves the beam’s ability to withstand bending moments by increasing its flexural strength.

Carbon Wrapping for Beams guarantees that load sharing is rebalanced throughout all structural components by reinforcing weak areas. This keeps tension from concentrating in one place. In other words, even with higher load demands, the structure starts to function like new.

Furthermore, the wrapping system is a flexible option because it readily adapts to both RCC and steel beams.

A Practical Solution for Indian Infrastructure

Many of the bridges, flyovers, and structures in India are older than thirty years. Their beams were made to meet various requirements and loads. These structures are subjected to increased traffic, weight, and environmental stress as cities grow.

A clever answer to this problem is Carbon Wrapping for Beams. It makes it possible to improve current beams without destroying them or stopping their use. For organizations that cannot afford downtime, such as businesses, hospitals, and schools, this is extremely beneficial.

Benefits Beyond Strengthening

Yes, the obvious advantage is strength. There’s more to it, though. Carbon Wrapping for Beams facilitates the effective transfer of both live and dead loads when used properly.

Additionally, it increases ductility, which enables the beam to undergo stress deformation without failing. In seismically active areas like Gujarat or Maharashtra, this is crucial. The covering also lessens additional corrosion or moisture-induced degradation.

Long-term maintenance and repair cost savings are a significant benefit for Indian projects with tight budgets.

Ideal Application Scenarios in India

The degree of involvement needed varies depending on the structure. Nonetheless, a large number of Indian buildings satisfy the beam strengthening requirements. The following are perfect situations:

- Beams that exhibit obvious fractures or overloading

- Buildings undergoing load enhancements, such as the addition of additional floors

- Retrofitting historic or public structures

- Buildings damaged by fire or earthquakes

- Corrosion-prone beams in coastal areas

Carbon Wrapping for Beams offers a dependable solution in each of these situations.

Step-by-Step Process of Carbon Wrapping

The application procedure calls for accuracy and knowledge. This is how it usually goes:

- Inspection: Find any weak spots or damaged areas.

- Surface Preparation: Level the surface and remove any paint, oil, and dirt.

- Application of Primer: To guarantee a strong bond, apply epoxy primer.

- Saturation: Dip sheets of carbon fiber into the resin.

- Wrapping: Carefully stack sheets around the beam.

- Curing: Give the resin enough time to solidify and adhere to the surface.

When expertly completed, the result is a beam that effectively manages the redistributed load.

Common Myths About Carbon Wrapping in India

Myths still make some property owners hesitant to use this approach. Let’s make things clear:

Myth: The cost is excessive.

Fact: It’s less expensive than steel jacketing or rebuilding.

Myth: Humidity makes it ineffective.

Fact: Contemporary resins are suitable for India and can withstand dampness.

Myth: Only big buildings can use it.

Fact: The benefits of residential and mid-rise buildings are equal.

By dispelling these myths, carbon wrapping for beams can become more widely used across the country.

Technical Standards and Compliance

International standards and IS regulations regulate construction in India. Although BIS has not yet standardized CFRP specifically, many engineers adhere to international standards such as:

- Design and application of ACI 440.2R

- For material behaviour, ASTM D7565

- For tensile testing, ISO 527

Certified materials and strict guideline adherence ensure safety and durability in Carbon Wrapping for Beams projects.

Challenges and Considerations

Even with its benefits, there are also some difficulties.

- Precision work requires skilled personnel.

- When obtaining materials, quality control is essential.

- It is necessary to control site conditions such as excessive heat or humidity.

However, these problems can be readily resolved with qualified contractors and appropriate oversight. Awareness and training are gradually getting better in Tier-2 and metro areas of India.

India needs long-lasting, reasonably priced, and environmentally friendly structural solutions. All three are provided by Carbon Wrapping for Beams. It is a clever reinforcing technique that facilitates effective load redistribution and goes beyond simple repair.

This method works well for both commercial buildings in Delhi and elderly residential societies in Mumbai. It’s worth looking into for your upcoming project if you’re a builder, contractor, or property owner.

Leave a Comment