Introduction to Induction Heating Machine Manufacturers

Induction heating machine manufacturers play a vital role in modern industrial production. These manufacturers design and build systems that provide accurate controlled and energy efficient heating for metal and conductive materials. As industries demand higher productivity better quality and lower operating costs induction heating technology has become an essential part of manufacturing processes.

Taylor Winfield Technologies is widely recognized among leading induction heating machine manufacturers for its advanced engineering capabilities and reliable industrial systems. The company develops equipment that supports both standalone heating applications and fully automated production lines. With decades of experience in industrial machinery and thermal processing Taylor Winfield continues to support manufacturers who require dependable heating solutions for demanding environments.

Induction heating technology offers a modern approach to thermal processing by generating heat directly within the material. This allows faster heating cycles better temperature control and reduced energy waste. These benefits make induction heating a preferred choice across automotive aerospace electrical heavy equipment and metal fabrication industries.

This article explores the working principles of induction heating the importance of choosing the right manufacturer the advantages of induction systems and the industrial applications where this technology delivers significant value.

Understanding Induction Heating Technology

Induction heating is a process that uses electromagnetic fields to generate heat inside a conductive material. Instead of heating the surrounding air or furnace chamber the system focuses energy directly into the workpiece. This results in rapid temperature rise and precise thermal control.

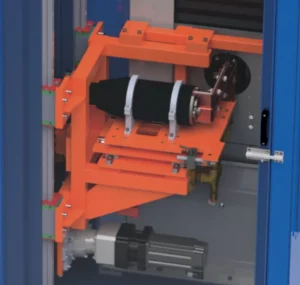

A typical induction heating system consists of a power supply an induction coil and a control unit. When alternating current flows through the coil it creates a magnetic field. This field induces electrical currents in the metal part. These currents generate heat due to the natural resistance of the material.

This method of heating offers superior accuracy when compared to traditional techniques such as flame heating or conventional furnaces. Manufacturers can target specific areas of a part and achieve uniform heating without affecting nearby components. This precision is especially important for processes that require controlled metallurgical changes.

Induction heating also provides a clean working environment. There is no combustion no smoke and no direct contact between the heating source and the part. This improves workplace safety and reduces environmental impact.

Role of Induction Heating Machine Manufacturers

Induction heating machine manufacturers are responsible for designing equipment that transforms this scientific principle into practical industrial solutions. Their role extends beyond building machines. They analyze customer requirements develop customized systems integrate automation and provide long term technical support.

Manufacturers like Taylor Winfield Technologies offer a wide range of induction heating systems including low power units for precision work and high power systems for large scale industrial production. These systems can be configured for various heating tasks such as hardening brazing forging soldering and preheating.

Custom engineering is one of the most important services provided by induction heating machine manufacturers. Every manufacturing operation has unique part sizes material types production volumes and quality standards. By tailoring system design manufacturers ensure optimal performance and efficiency for each application.

System integration is another key responsibility. Modern induction heating machines are often combined with robotic handling conveyors safety systems and real time monitoring tools. This allows seamless operation within automated production environments.

Advantages Offered by Induction Heating Systems

High Energy Efficiency

One of the strongest benefits of induction heating is its energy efficiency. Heat is generated only where it is needed which reduces energy loss. Traditional heating methods waste significant energy by warming surrounding air equipment and furnace structures.

Induction systems reach operating temperature quickly which shortens production cycles and reduces overall power consumption. Over time this leads to lower utility costs and improved sustainability for manufacturing facilities.

Energy efficiency also supports environmental goals by reducing carbon emissions associated with industrial heating operations.

Precise Temperature Control

Induction heating allows manufacturers to control temperature with exceptional accuracy. Operators can adjust power levels frequency and heating duration to achieve exact thermal profiles.

This precision is critical in applications such as surface hardening and brazing where specific temperature ranges determine final product quality. Consistent heating ensures uniform results across large production batches.

Modern systems often include digital controls and temperature sensors that provide real time feedback. This allows operators to monitor and adjust the process instantly which improves reliability and reduces scrap.

Rapid Processing Speed

Induction heating machines are capable of heating parts within seconds. This high speed performance increases throughput and enables manufacturers to meet demanding production schedules.

Shorter heating cycles also reduce bottlenecks in assembly lines. Parts move more quickly from one stage to the next which improves overall plant efficiency.

When combined with automation induction heating becomes even more powerful. Automated systems can process large volumes of parts continuously without interruption.

Improved Workplace Safety

Induction heating eliminates open flames hot surfaces and combustible gases. This significantly reduces the risk of fire and burns in the workplace.

Because there is no direct contact between the heating source and the material operators are less exposed to extreme temperatures. Noise levels are also lower than many traditional heating methods.

A safer working environment contributes to better employee well being and fewer production interruptions.

Environmentally Responsible Operation

Induction heating systems do not produce exhaust gases or harmful fumes. This makes them suitable for factories with strict environmental regulations.

Reduced energy usage further supports sustainability initiatives and helps manufacturers meet environmental compliance standards.

Industrial Applications of Induction Heating

Induction heating technology is used in a wide range of industrial processes where precise and reliable heating is required.

Heat Treatment Processes

Heat treatment is one of the most common applications of induction heating. This includes surface hardening tempering annealing and stress relieving.

Components such as gears shafts bearings and fasteners benefit from controlled heating that improves strength durability and wear resistance. Induction heating allows manufacturers to treat only the required areas which preserves the mechanical properties of the rest of the part.

Brazing and Soldering Operations

Brazing and soldering require accurate temperature control to melt filler materials without damaging base metals. Induction heating provides localized heating which ensures clean strong joints.

This is particularly valuable in electrical and electronic components where delicate parts must be protected from excessive heat.

Forging and Hot Forming

Forging operations require metal to be heated to high temperatures before shaping. Induction heating delivers rapid uniform heating which improves material flow and reduces defects.

The fast heating process also lowers oxidation and scale formation which enhances surface quality.

Preheating and Process Heating

Induction systems are often used to preheat parts before welding coating or machining. Preheating improves process consistency and reduces thermal shock.

In continuous production environments induction heating ensures stable temperatures throughout the manufacturing cycle.

Melting and Specialized Thermal Applications

Some induction heating machine manufacturers design systems for metal melting and specialized heating tasks. These systems support foundry operations research facilities and custom manufacturing projects.

Advanced applications may involve multi zone heating or vertical scanning systems that provide precise thermal control across complex geometries.

Choosing the Right Induction Heating Machine Manufacturer

Selecting the right manufacturer is essential for achieving long term success with induction heating technology.

A reliable manufacturer offers not only equipment but also engineering expertise and process knowledge. This helps ensure that the system is correctly designed for the specific application.

Key factors to consider include experience in similar industries customization capability automation integration options and availability of technical support.

Manufacturers like Taylor Winfield Technologies provide consultation during the early project stages to evaluate production goals and technical requirements. This collaborative approach leads to systems that deliver optimal performance from the first day of operation.

Long term service support is equally important. Access to spare parts training programs and field service technicians ensures minimal downtime and sustained productivity.

Research and development capabilities are another advantage. Manufacturers with in house testing facilities can validate processes and refine system designs before installation.

Technology Trends in Induction Heating Systems

Induction heating machine manufacturers continue to innovate as industrial requirements evolve.

Modern power supplies are becoming more compact efficient and flexible. Variable frequency technology allows a single system to handle multiple applications and material types.

Automation integration is also advancing rapidly. Induction heating systems are now commonly paired with robotic arms intelligent sensors and data monitoring platforms. This supports smart manufacturing strategies and improves quality control.

Energy management features are improving as well. New systems optimize power usage automatically based on load conditions which further enhances efficiency.

Manufacturers are also focusing on modular designs. Modular systems allow companies to expand capacity easily as production needs grow.

These advancements ensure that induction heating remains a future ready technology for industrial processing.

Importance of Induction Heating in Modern Manufacturing

Modern manufacturing demands precision speed efficiency and consistency. Induction heating meets all of these requirements.

By reducing cycle times and energy consumption manufacturers can improve profit margins while maintaining high quality standards.

The ability to integrate induction heating into automated lines supports large scale production without sacrificing accuracy.

For companies seeking to modernize their operations induction heating technology represents a strategic investment that delivers long term value.

Induction heating machine manufacturers play a central role in enabling this transformation by providing equipment that aligns with current and future production needs.

Conclusion

Induction heating machine manufacturers and every reliable induction heating machine supplier are essential contributors to the advancement of industrial thermal processing. Their systems enable fast precise and energy efficient heating for a wide variety of applications including heat treatment brazing forging and process heating.

Taylor Winfield Technologies stands among respected manufacturers in this field by offering advanced induction heating solutions designed for reliability automation and long term performance.

Through continuous innovation customization and technical support induction heating machine manufacturers and each experienced induction heating machine supplier help industries achieve higher productivity improved product quality and safer working environments.

As manufacturing continues to evolve the importance of induction heating technology will only grow. Companies that partner with an experienced induction heating machine supplier gain access to systems that support modern production demands and provide a competitive advantage in an increasingly technology driven industrial landscape.