Can Liquid Manufacturing Support Multi-Product Production?

In today’s fast-moving world, companies are always looking for better ways to produce high-quality products faster and more efficiently. One question that comes up often is: Can liquid manufacturing support multi-product production? The answer lies in the power of liquid manufacturing solutions, which are becoming a go-to choice for industries like pharmaceuticals, nutraceuticals, cosmetics, and food and beverage.

Nutra Best has explored how liquid manufacturing is not only capable of handling multiple products but also making the process smoother, cleaner, and more cost-effective.

What Is Liquid Manufacturing?

Liquid manufacturing is the process of producing products in liquid form. This includes syrups, creams, gels, lotions, oils, and more. It is widely used in industries where the end product must be in a fluid or semi-fluid form.

-

Vitamins and supplements

-

Health and beauty products

-

Medicinal syrups

-

Food-grade liquids like flavorings or additives

These applications require high precision, quality control, and flexibility, especially when multiple products are being manufactured on the same line.

Why Flexibility Matters in Production

Modern Business Needs Are Evolving

Companies today don’t just produce one or two products. They often offer entire product lines to cater to different customer preferences, health needs, or market demands. That’s where the need for a flexible production system comes in.

The Rise of Customization

Customers now want personalized solutions different flavors, ingredients, packaging, and concentrations. Nutra Best has noticed that more clients are requesting tailored options for different markets or age groups. A flexible system allows manufacturers to make quick changes without restarting the whole process.

How Liquid Manufacturing Solutions Enable Multi-Product Production

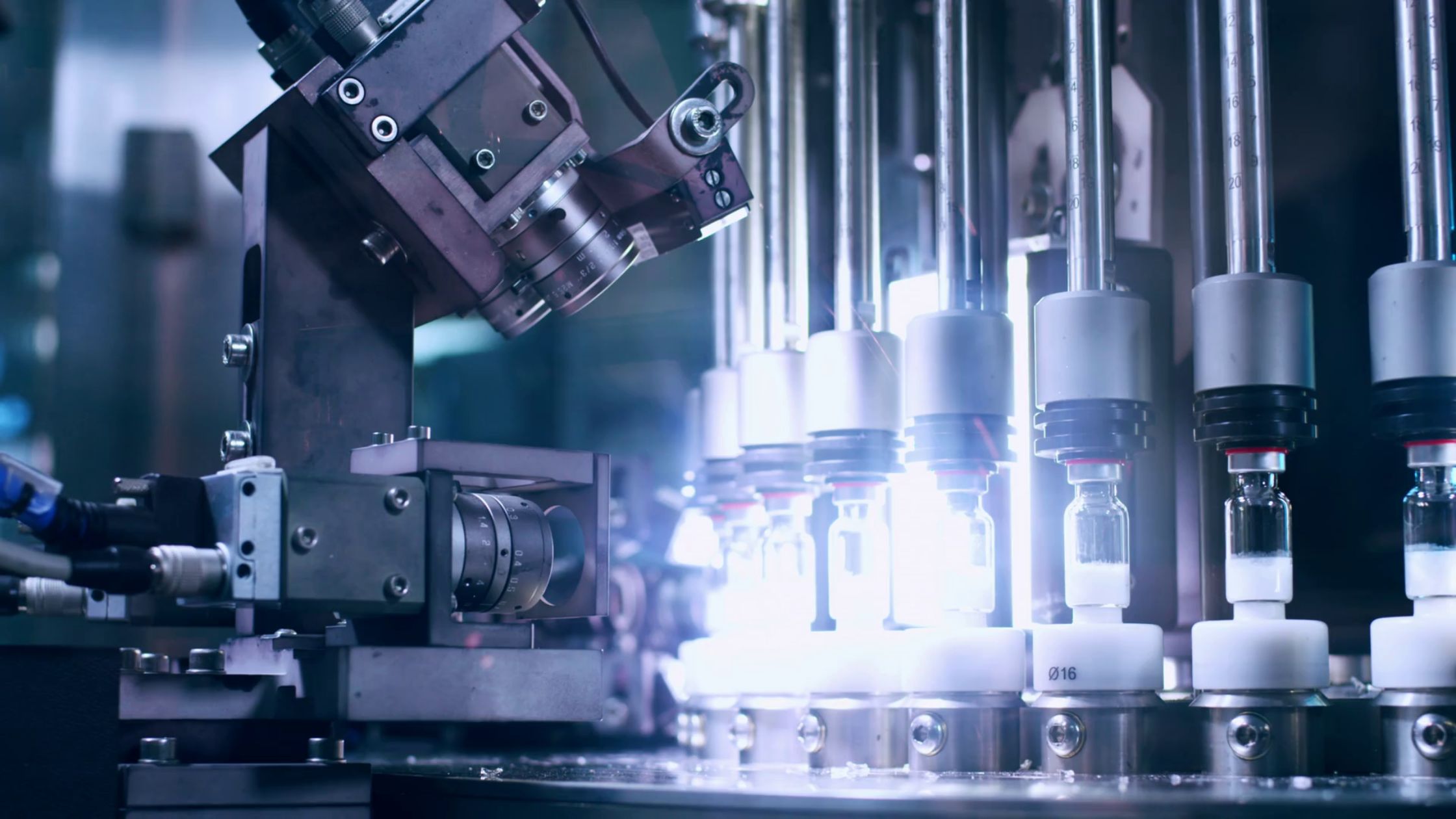

Advanced Equipment Design

Modern liquid manufacturing equipment is built with features that allow quick adjustments. These include:

-

Modular mixing tanks

-

Adjustable filling machines

-

Automated cleaning systems

These systems help companies like Nutra Best shift from one product to another with minimal downtime.

Recipe Management Systems

Digital recipe control allows the system to store and apply multiple product formulas. This is especially useful when handling a wide range of liquid products.

Batch-to-Batch Accuracy

Precision is key in multi-product production. Nutra Best relies on systems that offer tight controls on temperature, pH, viscosity, and dosing. This ensures each batch meets the required standards, even when the products are different.

The Role of Automation in Multi-Product Production

Faster Changeovers

Automation allows for faster switching between products. With minimal human intervention, operators can clean tanks, adjust settings, and load new materials all from a control panel.

Reduced Error Rates

When working with multiple formulas, manual errors are more likely. Automated systems reduce this risk by managing the critical steps of the production process consistently.

Real-Time Monitoring

Systems with built-in sensors and monitoring tools can give instant feedback. This helps operators keep the production on track and avoid delays.

Managing Cross-Contamination Risks

Importance of Clean-In-Place (CIP) Systems

Nutra Best uses Clean-In-Place systems that wash the inside of equipment without dismantling it. This allows for quicker and safer cleaning between different product runs.

Dedicated Tanks or Shared Equipment?

Depending on the nature of the products, manufacturers may choose between using separate tanks or shared ones with deep-cleaning features. High-potency items often require separate equipment to prevent cross-contamination.

Regulatory Guidelines

Following rules from organizations like the FDA or GMP is critical. Proper cleaning, documentation, and validation ensure that no residues carry over from one product to another.

Quality Control Across Multiple Products

Standard Operating Procedures (SOPs)

Nutra Best follows well-documented SOPs that detail how each product should be manufactured, inspected, and released. This ensures consistency, no matter how many different products are in the queue.

In-House Testing Labs

Having a testing lab allows for on-the-spot verification. Tests like viscosity checks, microbial tests, and active ingredient analysis help catch problems early.

Documentation and Tracking

Each batch is tracked from start to finish using software tools. These systems store data on ingredient usage, process times, temperatures, and test results, helping ensure traceability and compliance.

Cost Implications of Multi-Product Liquid Manufacturing

Initial Investment

Multi-product production systems cost more upfront due to the need for extra features like recipe storage, CIP systems, and advanced sensors. However, these costs are offset over time with higher output and fewer stoppages.

Lower Downtime

With systems designed for quick changeovers, manufacturers save time between product runs. This improves overall efficiency.

Better Use of Resources

Nutra Best has found that shared use of equipment and ingredients leads to better inventory control and cost savings in the long term.

Challenges and How to Overcome Them

Challenge 1: Training Staff

Operating modern systems for multiple products requires a well-trained workforce. Nutra Best offers hands-on training sessions for all team members to understand equipment, software, and cleaning processes.

Challenge 2: Scheduling Production

Running multiple products on the same line can cause scheduling issues. A well-planned production calendar helps balance the workload and avoid clashes.

Challenge 3: Ingredient Handling

Switching between different ingredients increases the risk of mix-ups. Color-coded containers, barcode systems, and digital inventory tools reduce this risk.

How Nutra Best Uses Liquid Manufacturing Solutions for Multiple Products

Product Lines Handled

Nutra Best produces a wide range of health and wellness products, including:

-

Liquid multivitamins

-

Herbal tonics

-

Protein drinks

-

Skin serums

Each of these has different manufacturing requirements, but the same system handles them all thanks to flexible design and automation.

Production Workflow

-

Recipe Upload – The selected formula is uploaded to the system.

-

Ingredient Preparation – Ingredients are weighed and loaded.

-

Mixing and Processing – The batch is mixed using automated controls.

-

Quality Check – Samples are tested mid-process.

-

Filling and Packaging – Bottles are filled, capped, and labeled.

-

Cleaning Cycle – CIP systems prepare the equipment for the next run.

Feedback Loop

Nutra Best collects feedback from its production team to improve processes over time. Any issues are documented and resolved before the next batch.

Sustainability in Multi-Product Liquid Manufacturing

Waste Reduction

Producing several products with the same setup helps minimize waste. Shared use of containers, packaging, and ingredients reduces leftover stock.

Energy Efficiency

Modern machines use energy only when needed. For example, heaters, mixers, and pumps are only turned on for the time required.

Eco-Friendly Packaging

Nutra Best uses packaging that is both recyclable and reusable, aligning its multi-product manufacturing with environmental goals.

What to Look for in a Multi-Product Liquid Manufacturing Partner

Experience and Expertise

Choose a manufacturer with proven success in handling diverse product lines. Nutra Best’s team brings years of experience to every production cycle.

Quality Certifications

Look for partners with certifications like GMP, ISO, or NSF. These ensure that the manufacturer follows best practices and regulatory standards.

Equipment Capabilities

Not all manufacturers have the right setup for multi-product lines. Ask if they have automated systems, recipe control, and flexible equipment.

Support Services

From product development to regulatory support, a full-service partner like Nutra Best can guide clients through every stage of the journey.

Final Thoughts

Can liquid manufacturing support multi-product production? The answer is a strong yes. With advanced equipment, automation, and strict quality controls, companies like Nutra Best can efficiently produce a variety of high-quality liquid products. Whether you’re launching a new health drink, vitamin tonic, or skincare product, flexible liquid manufacturing solutions make it all possible without compromising speed, safety, or quality.

Here. you can find more articles.

Leave a Comment