Looking for a reliable laser machine supplier to meet your industrial needs?

When it comes to industrial needs, whether for metal cutting, engraving, or etching, choosing the right laser machine supplier can make all the difference. Laser machines have become a vital tool across many sectors, from manufacturing and construction to artistry and design. But what should you consider when choosing the best supplier to provide high-quality, reliable, and efficient laser machines? Let’s dive deep into the factors that will help you make an informed choice and why it’s important to partner with the right supplier.

Understanding the Role of a Laser Machine Supplier

A laser machine supplier is not just someone who sells equipment; they act as a vital partner in ensuring your business has the right tools to execute precision work. Laser machines are used for a variety of purposes, from engraving intricate designs on materials to cutting metals with extreme accuracy. Therefore, when selecting a supplier, it’s crucial to understand what they bring to the table in terms of product quality, reliability, customer support, and after-sales service.

Laser machines are known for their precision and versatility, and this makes them ideal for industries that require high-quality, precise work. Whether you’re looking for a machine for industrial production or smaller, more intricate applications, your supplier must provide solutions that match your needs.

What Sets the Best Laser Machine Supplier Apart?

When you are searching for a laser machine supplier, several qualities will set the best suppliers apart from others. Here’s a breakdown of some key factors that make a supplier stand out:

-

Product Range and Customization Options

The right supplier will offer a broad selection of laser machines suited for various applications, including laser cutting, laser engraving, and laser marking. Additionally, a supplier who provides customization options can tailor the machines to suit your specific requirements. If you are in a niche market where specific features are required, working with a supplier that offers customization options is a huge advantage. -

Quality of Machines and Technology Used

The quality of the machines should be a top priority when selecting a supplier. Look for a supplier that uses the latest technology to manufacture laser machines. High-quality components and superior craftsmanship ensure the longevity and reliability of the equipment. Make sure the supplier offers machines with advanced features like high-speed processing, durability, and precision. -

Technical Support and After-Sales Service

A dependable laser machine supplier doesn’t just stop at selling you the machine; they should provide excellent after-sales support, including installation, maintenance, and troubleshooting. Ensure that the supplier has a solid reputation for customer service and offers fast responses to issues that may arise with your equipment. Suppliers who are known for their responsive technical support can save you a lot of time and hassle down the line. -

Global and Local Presence

Another important factor to consider is whether the supplier has a global or local presence. A global supplier can provide machines with internationally recognized certifications and compliance. Additionally, having a local distributor or representative can make a difference in terms of installation and service accessibility. -

Training and Resources

Some suppliers offer comprehensive training sessions to ensure that your team understands how to operate the equipment efficiently and safely. This can be an invaluable resource that helps you maximize the lifespan and capabilities of your laser machines. -

Pricing and Financing Options

Although price should never be the sole deciding factor, it’s essential to find a supplier that offers competitive pricing. Some suppliers may also provide flexible financing options, making it easier to invest in high-quality equipment without stretching your budget. -

Reputation and Reviews

Before choosing a laser machine supplier, check reviews and testimonials from other customers in your industry. If a supplier has a long track record of satisfied customers, it’s a good sign that they are reliable and provide top-notch products. Moreover, testimonials from businesses similar to yours can give you insight into how well the supplier’s machines perform in real-world applications.

Types of Laser Machines Offered by Leading Suppliers

Laser machines come in various types, each suited for different applications. Leading laser machine suppliers typically offer machines that specialize in:

-

Laser Cutting Machines

Laser cutting is one of the most common applications for industrial laser machines. Whether for cutting thin sheet metals or thicker materials, these machines use a focused laser beam to cut through materials with high precision. -

Laser Engraving Machines

Engraving machines are used to mark or engrave logos, text, and other designs onto materials such as metals, glass, or plastic. The precision and ability to work with different materials make these machines highly versatile in fields like branding, design, and art. -

Laser Marking Machines

Laser marking involves creating permanent marks or patterns on the surface of a material without affecting the material’s integrity. This technique is frequently used in industries like electronics, automotive, and aerospace. -

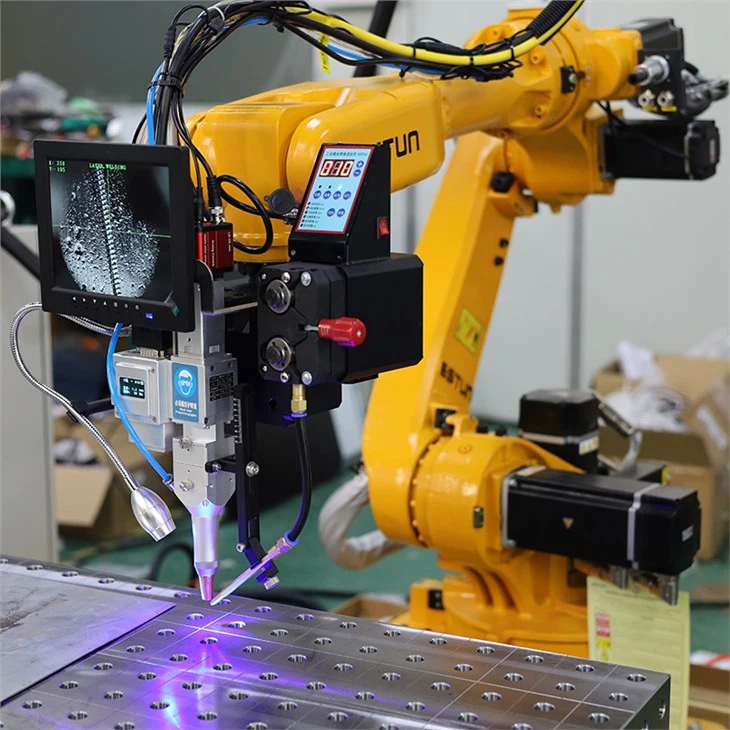

Laser Welding Machines

Laser welding uses a concentrated laser beam to join materials together with precision and speed. This type of laser machine is commonly used in high-end manufacturing, especially in the aerospace and automotive industries.

How to Ensure the Laser Machine Fits Your Needs

When working with a laser machine supplier, it’s important to evaluate your specific needs and ensure the equipment matches those requirements. Ask yourself:

-

What materials will I be working with?

-

What precision level do I need for my tasks?

-

How much space do I have for the laser equipment?

-

Will I need the machine to perform multiple tasks, like cutting, engraving, or welding?

By answering these questions, you can discuss your requirements with the supplier and choose the right machine for your business.

Working with Your Supplier

Once you have chosen the right supplier, collaboration doesn’t end at the purchase stage. Be sure to keep open lines of communication for any future needs. Whether it’s troubleshooting, seeking parts, or needing updates on new machine models, an ongoing partnership with your laser machine supplier will help ensure smooth operations in the long run.

Final Thoughts

Choosing the right laser machine supplier is a critical step in ensuring the success of your business, whether you’re focused on precision engineering, design, or large-scale production. A supplier who offers high-quality machines, excellent support, and reliable after-sales service will ensure that your laser machines continue to perform at their best for years to come. When evaluating suppliers, be sure to focus on the reputation of the supplier, the quality and range of machines offered, their technical support capabilities, and their customer service. By carefully considering these factors, you can forge a lasting partnership that supports the growth and success of your business.

Leave a Comment