Manufacture of Flip Top Caps

In the fast-paced world of consumer goods, packaging is more than just a container—it’s a critical touchpoint of the user experience. It’s the first interaction a customer has with your product and a daily reminder of your brand’s commitment to quality, convenience, and innovation. For brands seeking a dispensing solution that perfectly marries functionality with sleek design, the pull-push cap stands out as a market leader. At SupplePack, we don’t just manufacture caps; we engineer precision, reliability, and brand elevation into every single closure.

What is a Pull-Push Cap?

A pull-push cap, also known as a flip-top or sports cap, is a one-piece closure that operates on a simple, intuitive mechanism: pull to open, push to close. This user-friendly design offers controlled dispensing, perfect for on-the-go lifestyles. From sports drinks and water bottles to condiments, liquid soaps, and cleaning products, the pull-push cap provides a leak-proof seal that protects your product integrity while offering ultimate convenience for the end-user.

Why Partner with SupplePack as Your Pull-Push Cap Manufacturer?

Choosing the right manufacturing partner is crucial for ensuring your packaging meets the highest standards. SupplePack stands as a leader in the industry, offering unparalleled expertise and service.

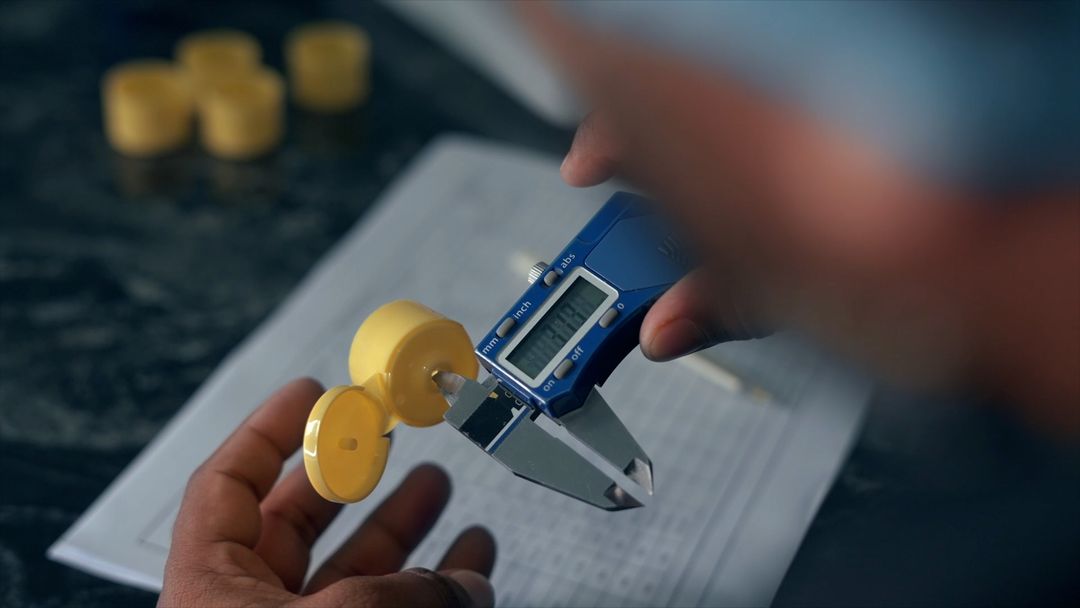

- Uncompromising Quality & Leak-Proof Performance: Our caps are engineered with precision tolerances. We utilize advanced molding technologies and rigorous quality control checks to ensure a perfect seal every time. This prevents leakage during transit and storage, safeguarding your product and your brand’s reputation.

- Superior Materials for Safety and Clarity: We use only 100% food-grade, FDA-compliant materials like Polyethylene (PE) and Polypropylene (PP). Our materials are chosen for their durability, chemical resistance, and excellent clarity (when applicable), ensuring your cap looks and performs flawlessly.

- Customization to Elevate Your Brand: Your packaging should be as unique as your product. SupplePack offers extensive customization options. Choose from a wide spectrum of standard colors or request a custom Pantone match. We provide options for embossing, debossing, and silk-screen printing to display your logo and branding with crisp, lasting quality.

- Designed for Compatibility: Our caps are designed to fit seamlessly with a wide range of bottle finishes, including the industry-standard 28mm neck. We work closely with you to ensure perfect compatibility with your chosen container, preventing costly production delays.

- Efficiency and Scalability: We understand the demands of modern supply chains. Our manufacturing processes are optimized for high-volume output without sacrificing quality. Whether you need a large run for a flagship product or a smaller batch for a market test, SupplePack delivers on time and to spec.

The SupplePack Promise

When you choose SupplePack, you’re choosing more than a component supplier. You’re choosing a strategic partner dedicated to your success. We are committed to providing innovative packaging solutions that enhance your product, resonate with your customers, and drive growth.

Ready to revolutionize your packaging? Contact the SupplePack team today to discuss your project requirements, request samples, and discover how our Manufacture of Pull Push Caps can become a valuable asset to your brand.

Frequently Asked Questions (FAQ)

Q1: What materials are SupplePack’s pull-push caps made from?

A: We exclusively use high-quality, food-grade plastics like Polypropylene (PP) and Polyethylene (PE). These materials are FDA-compliant, BPA-free, and chosen for their durability, safety, and excellent sealing properties.

Q2: Are your caps leak-proof?

A: Absolutely. Leak-proof performance is a cornerstone of our design. Each cap undergoes stringent testing to ensure it forms a hermetic seal with the bottle, preventing leaks during transportation, storage, and consumer use.

Q3: Can I customize the color of the caps?

A: Yes. We offer a wide range of standard colors and can also provide custom color matching to your specific Pantone code, ensuring your caps perfectly align with your brand identity.

Q4: Do you offer branding options on the caps?

A: We do. We can apply your logo, instructions, or other branding elements through high-quality silk-screen printing. We also offer embossing and debossing for a premium, tactile feel.

Q5: What bottle neck sizes are your pull-push caps compatible with?

A: Our caps are most commonly designed for the standard 28mm neck finish, which is widely used in the industry. However, we can manufacture caps to fit various neck sizes. Please contact us with your specific requirements.

Q6: What is your minimum order quantity (MOQ)?

A: Our MOQ varies depending on the customization level. We strive to be flexible to accommodate both large-scale productions and smaller pilot projects. Please get in touch with our sales team to discuss your needs.

Q7: Can I request samples before placing a full order?

A: Certainly. We highly encourage it. We are happy to provide samples of our standard pull-push caps so you can evaluate their quality, functionality, and fit for your product.

Q8: Where are your manufacturing facilities located?

A: SupplePack’s state-of-the-art manufacturing plants are strategically located to ensure efficient production and logistics. For specific details, please contact our team.

Q9: Do you provide support with cap design and selection?

A: Yes, our team of packaging experts is here to assist you. We can help you select the ideal cap for your product type, viscosity, and target market, ensuring optimal performance and consumer satisfaction.

Leave a Comment