The Benefits of a Plexiglass Enclosure for Your Prusa 3D Printing

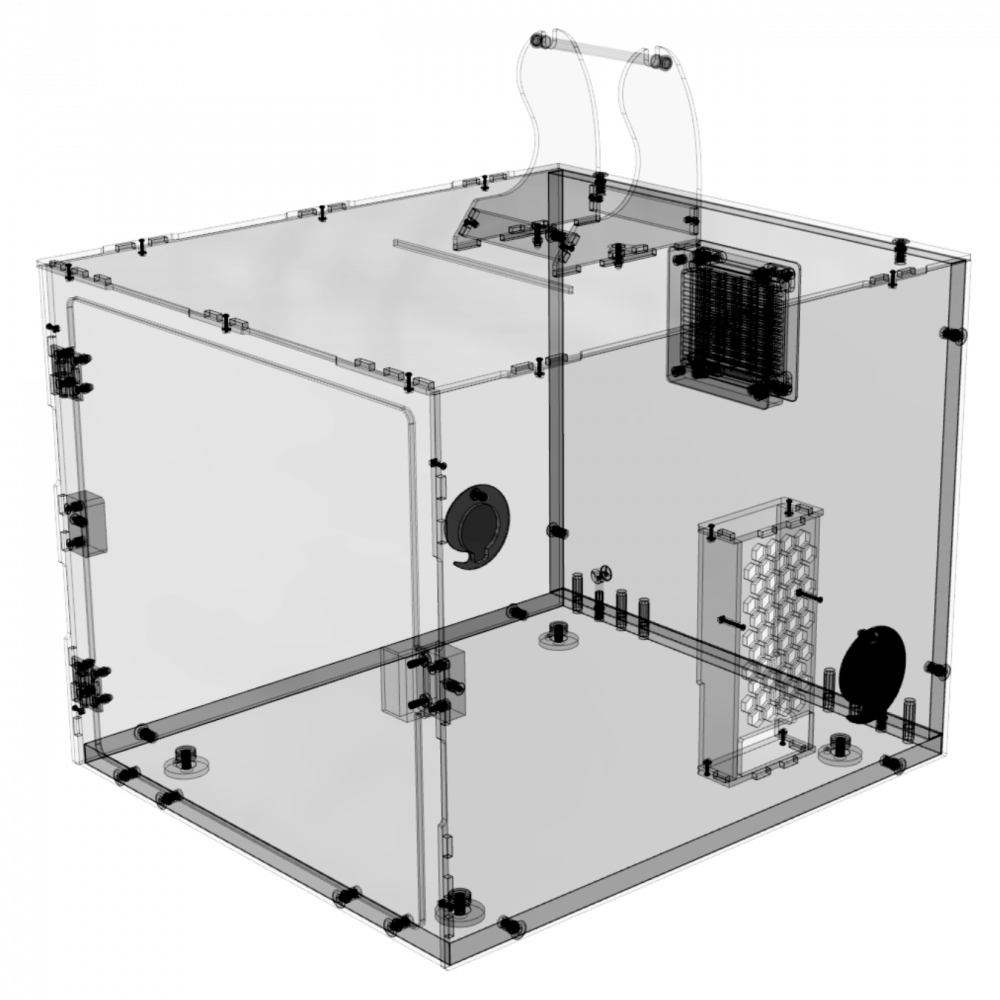

3D printing has evolved from a hobby into a professional-grade tool for designers, engineers, and makers. One upgrade that significantly enhances performance is adding a prusa enclosure plexiglass setup. This simple yet powerful addition creates a stable printing environment, improves safety, and helps deliver consistent results with every project.

Why an Enclosure Matters

3D printers are sensitive machines. Even minor fluctuations in temperature, drafts, or dust can lead to warped layers, uneven adhesion, or complete print failure. A plexiglass enclosure surrounds your Prusa printer with a transparent, protective housing that helps maintain optimal conditions while letting you observe the printing process in real time.

Stable Printing Environment

A controlled environment is essential for materials like ABS, PETG, and Nylon, which can warp when exposed to uneven cooling. The enclosure traps heat inside and prevents sudden temperature drops, helping layers bond evenly and improving structural integrity.

Reduced Print Failures

Print failures can waste time and filament. By keeping the internal climate steady, a plexiglass enclosure minimizes splitting, cracking, and warping—especially important for large or intricate builds that take hours to complete.

Improved Safety for Your Workspace

3D printers operate with high temperatures—nozzles and heated beds can reach levels that cause serious burns. An enclosure serves as a physical barrier, reducing the chance of accidental contact.

Additionally, some filaments release fine particles and fumes when melted. A well-designed plexiglass enclosure can help contain these emissions and, when combined with proper ventilation or filtration, provide a cleaner and safer workspace.

Noise Reduction for a Better Work Environment

If you run your printer in a home office, workshop, or shared space, you know how noisy a print can get. The constant hum of motors and fans becomes distracting over long periods. Plexiglass enclosures dampen sound, reducing noise levels and making your environment far more pleasant—especially for long, multi-hour prints.

Dust and Debris Protection

Dust and small particles can accumulate on the moving parts of your printer, such as rods, bearings, and belts. Over time, this buildup affects performance and may lead to mechanical wear. An enclosure acts as a shield, keeping out dust and helping your printer operate smoothly for longer.

Energy Efficiency and Cost Savings

Maintaining a warm, stable environment inside the enclosure means your printer doesn’t have to work as hard to sustain nozzle and bed temperatures. This reduces energy consumption and saves money over time. Fewer failed prints also mean less wasted filament—a direct cost-saving advantage, especially for frequent or large-scale projects.

Aesthetic Appeal and Professionalism

Beyond functionality, a plexiglass enclosure adds a sense of sophistication and modernity to your Prusa setup. Its sleek, transparent panels allow you to watch every stage of the printing process, transforming your 3D printer from a simple tool into a display-worthy centerpiece. This not only enhances your personal workspace but also makes a strong visual impression on anyone who sees it in action.

For small businesses, the professional look of an enclosed printer can instill confidence in clients and partners. It reflects attention to detail, commitment to quality, and a dedication to maintaining a clean, organized environment. A visually appealing setup can even elevate your brand’s image, making your workshop, studio, or office feel more like a high-tech production facility rather than just a creative space.

Choosing the Right Plexiglass Enclosure for Your Prusa

When selecting an enclosure, there are a few key factors to consider:

Size and Compatibility

Ensure the enclosure fits your specific Prusa model. Some are designed for popular models like the Prusa i3 MK3 or Prusa XL, while others are universal but may require adjustments.

Accessibility and Usability

Look for doors or removable panels that make loading filament and removing completed prints simple. Easy access is especially important for high-volume printing where speed and efficiency matter.

Ventilation and Filtration Options

While plexiglass enclosures help contain particles, adding ventilation or a filtration system provides extra safety—particularly when working with filaments known to produce fumes.

Build Quality and Durability

High-grade plexiglass resists scratches, retains clarity, and withstands regular use. Investing in quality materials ensures long-lasting performance and better overall results.

DIY vs. Pre-Built Enclosures

Both DIY and pre-built options have their advantages:

- DIY Kits – Cost-effective, customizable, and great for hobbyists who enjoy building their setup. However, they may require tools and assembly skills.

- Pre-Built Enclosures – Professionally finished, ready to use, and designed to perfectly fit your printer model. They cost more but save time and effort.

Your choice depends on your budget, skill level, and how quickly you need a reliable solution.

Final Thoughts

Upgrading your Prusa printer with a plexiglass enclosure is one of the best ways to enhance print quality, safety, and efficiency. It’s not just a cosmetic upgrade—it’s a performance booster that protects your printer, reduces noise, and keeps your workspace cleaner.

Whether you’re a hobbyist printing creative models at home or a professional running production-level prints, this simple addition can take your results to the next level.

Leave a Comment