PP Jumbo Bags for Heavyweight Industrial Storage Solutions

A Trusted Bulk Packaging Choice

For industries managing large materials, efficient and safe packaging is key. Industries with large scale operations, such as agriculture, chemicals, construction and mining, usually expect to use high capacity solutions to facilitate storage and transport of goods. One of the most trusted packaging options in these spaces is the PP jumbo bag. These bags are trusted as a strong, reliable and economic means of storing bulk products. They represent a simple way to bulk store a product. Instead of having to store materials in multiple smaller containers, the PP Jumbo Bags Suppliers in India greatly reduce the labour while still using an easy to manage bag for storage and handing purposes at this scale. Since they operate with very little risk to tear and damage to massive loads during transportation, they are an integral part of the logistics for large scale operations.

Industrial Applications and Versatility of Use

These bags are used throughout several industries for the movement of granular and powdery or semi-solid materials. In agriculture they are used for handling grains, fertilizers, and seeds. The construction industry uses them to handle sand, gravel, and cement. Chemical plants find them valuable for storing and moving powders, resins, and other materials. Their ability to safely carry heavy weight and, sometimes, hazardous materials has made them a standard solution in warehousing and distribution. And it is the efficiency of bulk transport that has made them popular in these settings. The versatility and durability of these bags continue to serve a purpose in environments that require bulk transport of goods.

Safety and Load Efficiency for Better Handling

When it comes to load-bearing capacity, PP jumbo bags can be designed to carry from 500 kg to over 2000 kg depending on size and construction. They are designed to disperse weight evenly, so if bag failure occurs, it will be minimized during lifting or transportation. Additional features like UV protection, anti-static, and food-grade certification can also open up usage in certain applications. Of course, these enhancements also protect both the product itself and workers and equipment, so the company can support safe and productive operations.

Environmental Impact and Reusability Benefits

Many varieties are designed to be used several times over, which decreases overall packaging waste. And since the bags are constructed of polypropylene, they are recyclable if done properly, and aligned to sustainability goals. By using polypropylene jumbo bags instead of single-use sacks, industries can save money on packaging costs while having a cleaner impact on the environment. The bags are also lighter in weight, so they will save carbon emissions while being shipped, making them a more responsible option in today’s supply chain.

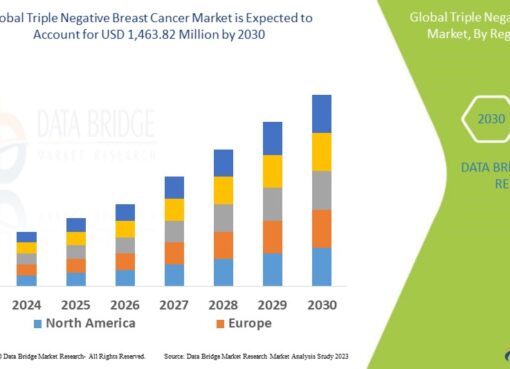

Wider Acceptance and Global Trends

As more companies choose efficient and safe bulk handling, the acceptance of this packaging solution has gone up significantly worldwide. Companies from all over the world are focusing on strong reusable packaging options that create less waste and still keep the products in good condition. The consistency of performance from PP Woven Jumbo Bags has significantly made a case for them in the bulk bag market. As industries start to focus more on sustainable logistics, the global market is expected to grow even more. There is also enough innovation coming in design and production to ensure that these bags continue to comply with international safety and performance specifications.

Role of Quality Producers and Market Reach

The importance of trustworthy producers, to ensure quality cannot be overstated. With demand for high-capacity packaging consistently increasing, manufactured PP jumbo bags are being produced at a higher capacity than ever. PP jumbo bags producers have developed tailored solutions, meeting specific preferences of an area of industry which may consist of options in coating thickness, a safety liner, or mechanisms for lifting. With the broad availability of PP jumbo bags from numerous suppliers in India, it is equally easy for businesses to buy these bags in bulk, allowing for a sealed delivery, without compromising any quality . Cheaper prices, competition in the market helps buyers benefit of tested solutions relevant to their requirements for use.

Key Features That Add to Their Value

Features such as spouts for easy filling, bottom discharge for controlled emptying, and a variety of lifting loop configurations all streamline the operational process. Some bags even come with baffles to assist the bag in retaining shape and stackability for better storage. These action value elements save space and loading time while increasing overall workflow. These bags are consistently reliable with little to no anticipated breakdowns in material transport settings—whether in the warehouse or outdoors. The added ability to use forklifts or cranes makes the bags an easy and useful addition, as they can integrate easily with either fully automated or manual until to handle the bags with flexibility and ease.

Conclusion

With the demand for large volume packaging overall safety and efficiency, PP jumbo bags have become essential in diverse industries. They are durable, so they can be used in various ways and are an environmentally friendly option; therefore, jumbo bags provide another level of functionality and performance over conventional packaging. As industry requirements only become better, smarter, safer and more sustainable, this raises the standard for bulk material handling; so, it is essential that industries source from proven PP Jumbo Bags Manufacturers and suppliers who have created all-around quality jumbo bags with functionality that will support high performance; therefore, providing an industry better opportunity for sustained operational efficiency, high performance and excellence.

Frequently Asked Questions

What materials are used to make these bags?

These bags are made from a woven polypropylene fabric called “poly bag.” The material is durable, flexible, and resistant to moisture, making it an ideal choice for heavy-duty use.

Are they safe for food products?

Many producers are certified, and bags made of food-grade fabric can safely transport grains, flour, sugar, and other foods.

Leave a Comment