Sheet Metal Manufacturing: A Comprehensive Guide

Sheet metal manufacturing is a fundamental process in modern industries, enabling the creation of durable and precise metal components used in a variety of applications. From automotive and aerospace to construction and electronics, sheet metal fabrication plays a crucial role in shaping the products we use daily.

What is Sheet Metal Manufacturing?

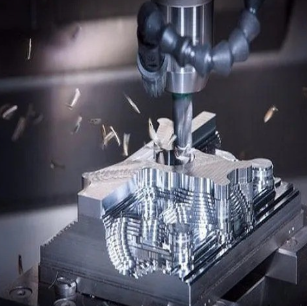

Sheet metal manufacturing involves cutting, bending, and assembling metal sheets into desired shapes and structures. The process is used to create components ranging from simple brackets to complex enclosures and structural elements.

Key Processes in Sheet Metal Manufacturing

- Cutting: The first step in fabrication, cutting is performed using methods such as laser cutting, plasma cutting, water jet cutting, and shearing to achieve precise dimensions.

- Bending: Using press brakes and other specialized machinery, metal sheets are bent into specific angles and shapes to meet design requirements.

- Punching: This process involves creating holes, slots, or other cutouts using a punch press for functional or aesthetic purposes.

- Welding and Assembly: Different parts are joined together through welding, riveting, or fastening techniques to form complete components or structures.

- Finishing: To enhance durability and appearance, metal parts may undergo surface treatments such as powder coating, anodizing, or galvanization.

Materials Used in Sheet Metal Manufacturing

Common materials used in sheet metal manufacturing include:

- Stainless Steel: Offers high strength and corrosion resistance.

- Aluminum: Lightweight and resistant to rust, ideal for aerospace and automotive industries.

- Copper: Excellent conductivity makes it suitable for electrical applications.

- Carbon Steel: Durable and cost-effective for structural components.

Advantages of Sheet Metal Manufacturing

- High Precision: Advanced CNC technology ensures accurate and consistent production.

- Cost-Effectiveness: Suitable for both prototyping and mass production, reducing material waste.

- Durability: Metal components offer superior strength and longevity compared to plastic alternatives.

- Design Flexibility: Various forming and cutting techniques allow for complex and customized designs.

Applications of Sheet Metal Manufacturing

- Automotive: Body panels, chassis components, and exhaust systems.

- Aerospace: Aircraft frames, engine parts, and structural supports.

- Electronics: Enclosures, brackets, and heat sinks.

- Construction: Roofing panels, structural beams, and HVAC ducts.

Future Trends in Sheet Metal Manufacturing

With advancements in automation, robotics, and AI-driven fabrication, sheet metal manufacturing is becoming more efficient and precise. The integration of 3D printing, digital modeling, and smart manufacturing techniques is expected to further revolutionize the industry, enabling faster production and enhanced customization.

Conclusion

Sheet metal manufacturing remains a cornerstone of modern industrial production, providing high-quality and durable components for diverse applications. As technology continues to evolve, businesses leveraging advanced fabrication techniques will gain a competitive edge in producing efficient, cost-effective, and innovative metal products.

Leave a Comment