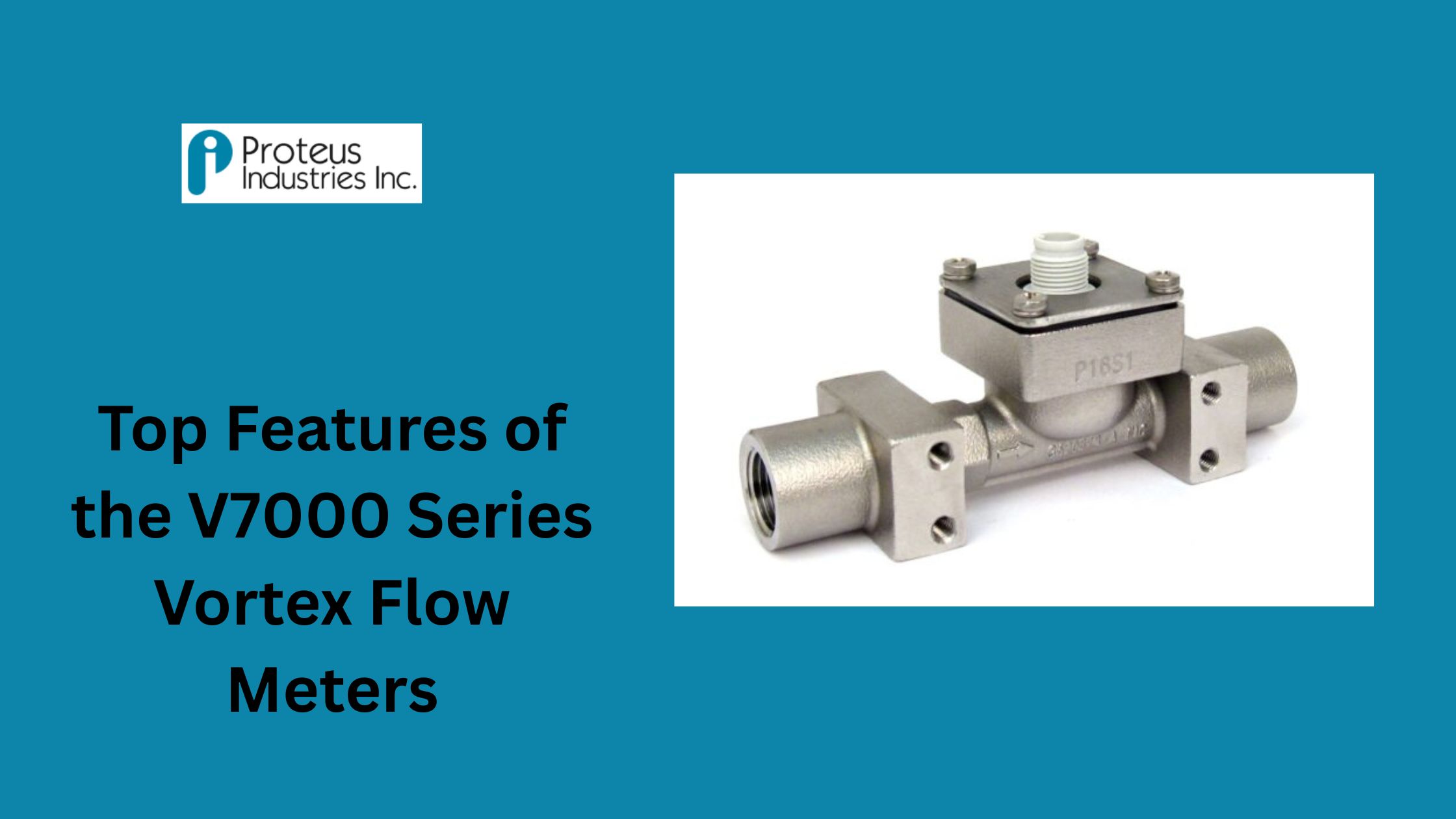

Top Features of the V7000 Series Vortex Flow Meters

Accurate flow measurement is critical in industrial processes where efficiency, safety, and cost-effectiveness depend on precise monitoring. Traditional flow meters often face limitations, including inconsistent accuracy, reduced durability, and limited versatility, when exposed to harsh operating conditions. To overcome these challenges, industries are increasingly adopting the V7000 Series Vortex Flow Meters, a modern and reliable solution designed for diverse applications. Known for their robustness and precision, these meters have become essential in various sectors, including oil and gas, power generation, and water treatment. This article highlights the most important features buyers should look for when selecting the V7000 Series for their operations.

What Are V7000 Series Vortex Flow Meters?

The V7000 Series Vortex Flow Meters operate on the principle of vortex shedding, where a bluff body placed in the fluid stream creates vortices proportional to the flow velocity. Sensors detect these vortices and convert the frequency into accurate flow measurements. Unlike conventional flow meters, the V7000 Series delivers precision without requiring frequent calibration or complex maintenance. They can measure not only water but also gases and steam, making them highly versatile. Industries prefer these meters for their durability, reliability in fluctuating conditions, and compatibility with modern control systems, making them a superior alternative to many traditional meters.

Features to Look for in V7000 Series Vortex Flow Meters

High Accuracy and Reliability

One of the most important features of the V7000 Series Vortex Flow Meters is their ability to deliver precise and consistent readings under varying conditions. Whether in fluctuating flow rates or challenging industrial environments, accuracy ensures operational efficiency, reduces resource wastage, and improves overall process control.

Durable Construction

These meters are built to withstand tough industrial environments, including high pressure, elevated temperatures, and corrosive conditions. Their rugged construction ensures long-lasting performance, even in sectors such as oil and chemical processing, where durability is essential for uninterrupted operations.

Fluid Versatility

Another key feature is versatility. The V7000 Series Vortex Flow Meters can measure not only water but also gases and steam with the same device. This adaptability enables industries to standardise measurement tools across multiple processes, thereby reducing equipment costs and enhancing operational efficiency.

Advanced Signal Processing

Modern V7000 Series devices incorporate advanced digital signal processing to filter out noise and minimise measurement errors. This ensures stable and reliable readings, even in environments with vibrations or electromagnetic interference, giving industries confidence in their data.

Easy Integration

Today’s industries rely heavily on automation, and the V7000 Series Vortex Flow Meters are designed to integrate seamlessly with control and monitoring systems. Their compatibility with digital communication protocols ensures smooth operation, enabling better decision-making and efficient process management.

Low Maintenance Design

With minimal moving parts, the V7000 Series requires less maintenance compared to traditional flow meters. This design reduces downtime, lowers service costs, and ensures consistent performance, making it a cost-effective choice for long-term industrial use.

Why These Features Matter?

The features of the V7000 Series Vortex Flow Meters translate directly into measurable benefits for industries. Enhanced accuracy leads to greater operational efficiency, while durable construction ensures system reliability in demanding environments. Fluid versatility reduces the need for multiple devices, thereby cutting costs. Advanced signal processing and seamless integration support automation, compliance, and safety. Ultimately, low-maintenance designs minimise downtime, thereby enhancing long-term productivity. These advantages address critical challenges across industries, including oil and gas, chemical processing, power generation, and water treatment, making the V7000 Series indispensable in modern operations.

How to Choose the Right V7000 Series Vortex Flow Meter?

1. Consider the Type of Fluid

The V7000 Series Vortex Flow Meter selection begins with understanding the fluid being measured: liquids, gases, or steam. Different fluids have unique properties, and matching the meter to the fluid ensures reliable performance, precise readings, and long-term operational efficiency.

2. Evaluate the Flow Range

Each industrial application operates within specific flow ranges. Choosing a V7000 Series meter designed for the expected minimum and maximum flows ensures accuracy across varying conditions, prevents measurement errors, and maintains process stability in demanding environments.

3. Assess Operating Conditions

Pressure, temperature, and vibration directly affect meter performance. The V7000 Series Vortex Flow Meters are engineered for tough conditions, but ensuring compatibility with the actual environment prevents failures, reduces downtime, and extends equipment lifespan in industrial applications.

4. Check Industry-Specific Requirements

Industries such as food manufacturing require high hygiene standards, while the oil and gas industry demands strict safety compliance. Selecting the right V7000 Series model tailored to industry-specific regulations guarantees safe operation, legal compliance, and consistent performance within specialised applications.

5. Balance Investment and ROI

While upfront costs are important, the long-term return on investment is more crucial. The V7000 Series offers durability, low maintenance, and operational efficiency, delivering greater value over time and reducing overall expenses through consistent accuracy and reduced downtime.

Conclusion

Selecting the V7000 Series Vortex Flow Meters is crucial for industries seeking to enhance accuracy, efficiency, and long-term reliability. By focusing on features such as precision, durability, versatility, advanced processing, and easy integration, businesses can achieve greater process control and lower operational costs. These meters address critical challenges faced by traditional flow measurement technologies, making them an indispensable tool in modern industrial operations. Companies should carefully evaluate their specific requirements before investing to maximise benefits and ensure long-term success.

Leave a Comment